About Us

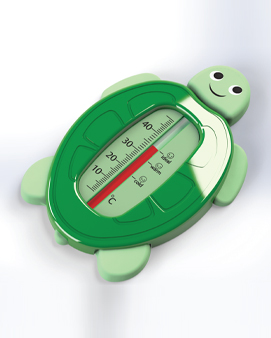

Kasem International Co. Ltd., was established in March 2003 to focus on manufacturing Products with food contact, which needs the best hygienic manufacturing and quality processes. A new state of the art manufacturing facility was built to focus on quality products to be made in a very Hygienic conditions. Today, it is one of Thailand’s fastest growing manufacturer of high quality food contact products in baby feeding and Kitchen ware industry.

Read MoreWhy Us

The company’s consistently excellent standards of production, quality process and customer care have made us the choice of leading brands and retailers in 20 countries across the globe. They recognize us for delivering innovative products, manufacturing excellence and technical solutions.

Work with Us

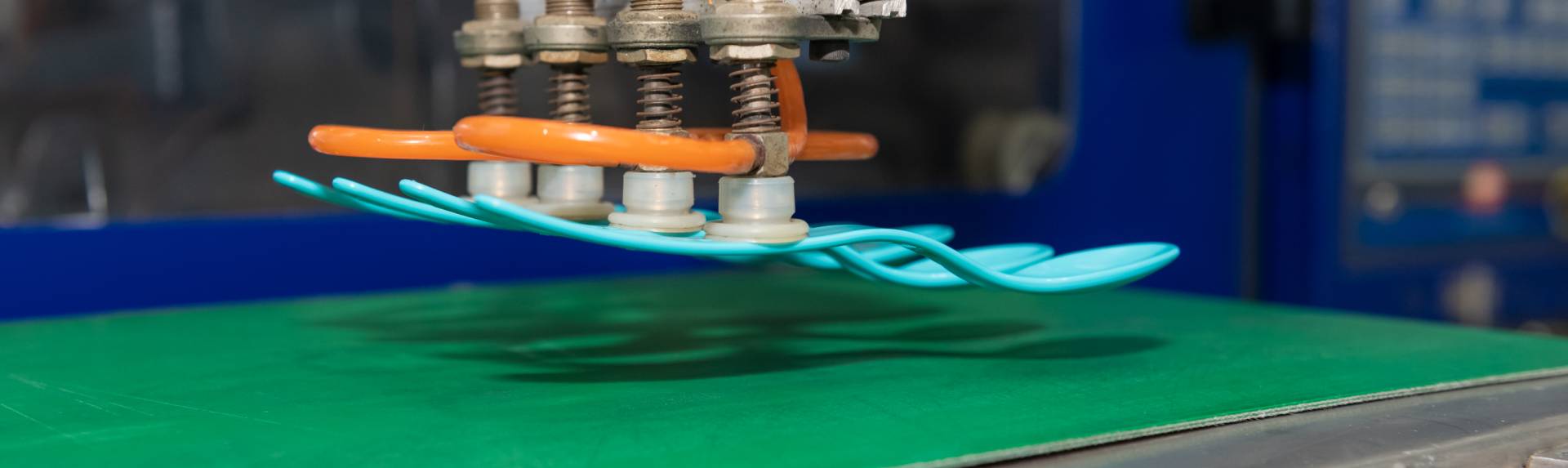

Injection Molding

Product Development

Quality Focus

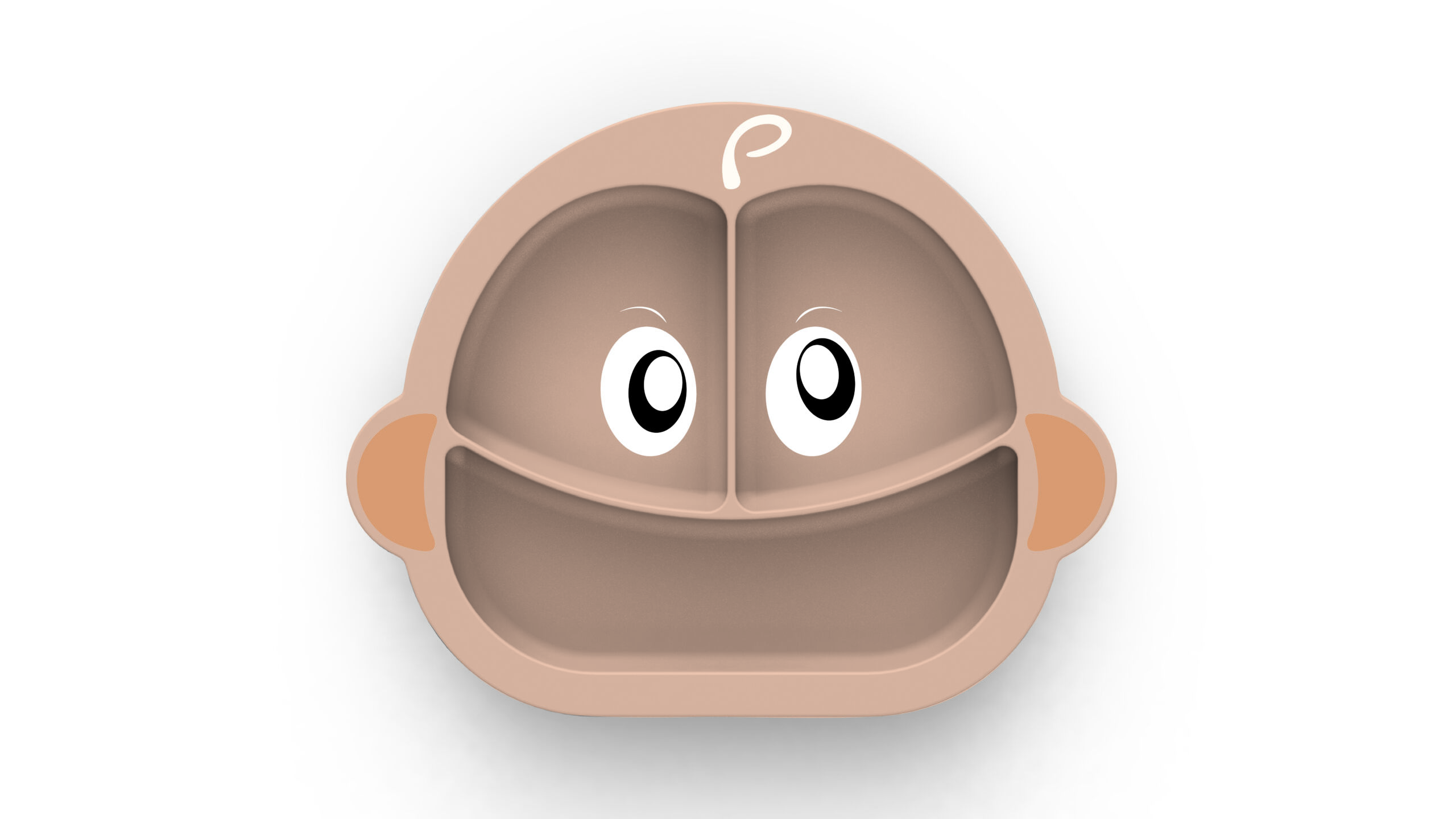

Our Products

We offer extensive experience and know-how in custom-built consumer products for Baby Feeding and Food Ware categories. This includes, for example, the development of premium baby pacifier which needs very high manufacturing care as it needs 100% safety for babies to avoid choking hazard.

Collaboration & Development

Our product development teams work closely with clients to shape the product specification. After that, our highly qualified team of experienced engineers design and develop the product in a way that is fit for mass manufacturing.

Concept Creation

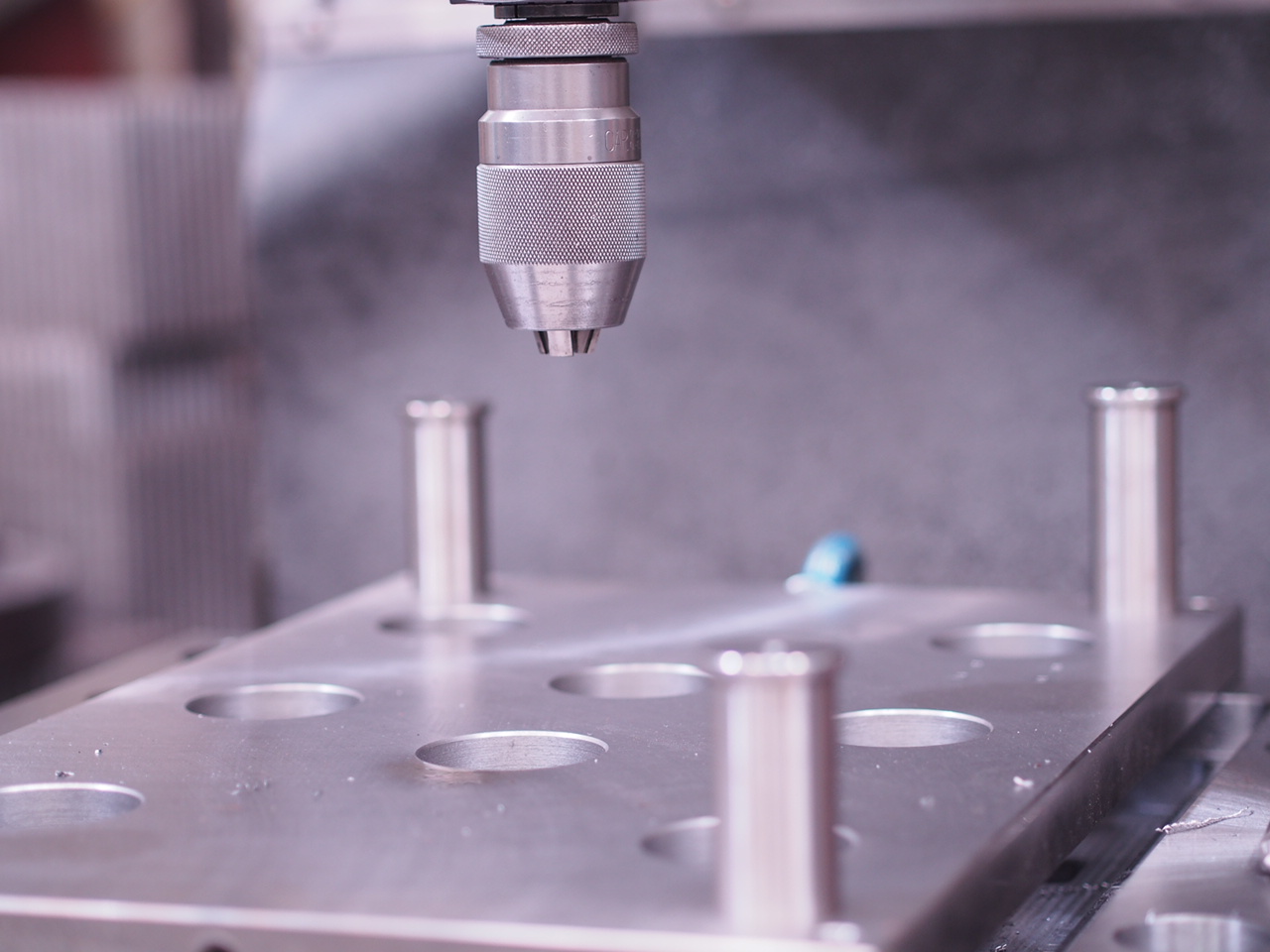

Kasem’s hallmark is collaborating with its customers during the development phase to translate consumer insights into value propositions. Together, we share our design and engineering expertise and listen carefully to our customers who express valuable market and consumer intelligence. This combined knowledge creates the leading edge needed to manufacture innovative, consumer-orientated products.Once designs are ready, our in-house model shop can rapidly prototype the 3D CAD files to accurate parts within hours. This is achieved by the use of a range of rapid prototyping services : CUBE, SLS, CNC, silicone casting. This process is crucial as it allows testing and verification of both engineering and aesthetic aspects

-

Ideation

Ideation -

Industrial Design

Industrial Design -

Rapid Prototyping

Rapid Prototyping

Design & Development

Kasem’s capabilities include conceptual and 3D modelling for development of new products. Software is used throughout product development; Solid Works for 3D CAD design

-

Design X Factor

Design X Factor -

Fit For Use

Fit For Use -

Mechanical Engineering

Mechanical Engineering

Engineering

Our engineers develop the product fit for mass manufacturing. All products are put through rigorous abuse and life testing to ensure “Fit For Use”. Our in-house Testing Laboratory ensures that all prototypes and products meet requirements.

-

Product Validation

Product Validation -

Life-Cycle Management

Life-Cycle Management -

Molding & Data Verification

Molding & Data Verification -

Industrialization

Industrialization -

Tool Development And Material Selection

Tool Development And Material Selection

Packaging

Kasem works collaboratively with our customers to create innovative retail display packaging and product display solutions that communicate your brand message.

-

Packaging Design For Blister And Clamshell Pack

Packaging Design For Blister And Clamshell Pack -

Packaging Design For High Quality Gift And Display Box

Packaging Design For High Quality Gift And Display Box -

Packaging Design For Shelf-Ready Packaging (SRP) Or Retail-Ready Packaging (RRP)

Packaging Design For Shelf-Ready Packaging (SRP) Or Retail-Ready Packaging (RRP)

Our Journey

A humble beginning. Manufacturing excellence for more than 5 decades. Pride of Thailand since 1964.

Kasem Plastic is established, specialized plastic injection molding.

The factory moved to the Bangbon premises 3600 sqm.

In house at Bangbon started mold making.

Kasem Plastic Industries was established, the second factory at Chonburi (7000 sq m).

Upgraded Mold makings included CNC, milling machines and 3D mold design.

Kasem International was established, Started manufacturing baby accessories products

Stared Making 3D Modeling with Solid Work.

expanded production and warehouse area by 5000 sqm

expanded plastic injection with 8 additional machines

invested in Siemens NX CAD software to upgrade product development

Our Partners

Our strategic objective is to create value for our customers and partners. We try to surpass our partner's expectations through manufacturing excellence, integrity and transparency and fairness. Our core values have gained us the global footprints with trusted and respect in 20 countires across the globe.

Medical devices

Medical devices