Exploring the Environmental Impact of Plastic Injection Molding

Plastic injection molding has revolutionized manufacturing across industries, offering efficiency, precision, and versatility. However, as we delve deeper into its applications, it’s essential to consider its environmental implications. In this blog, we’ll explore the environmental impact of plastic injection molding techniques and shed light on sustainable practices within the industry.

1. Understanding Plastic Molding Techniques

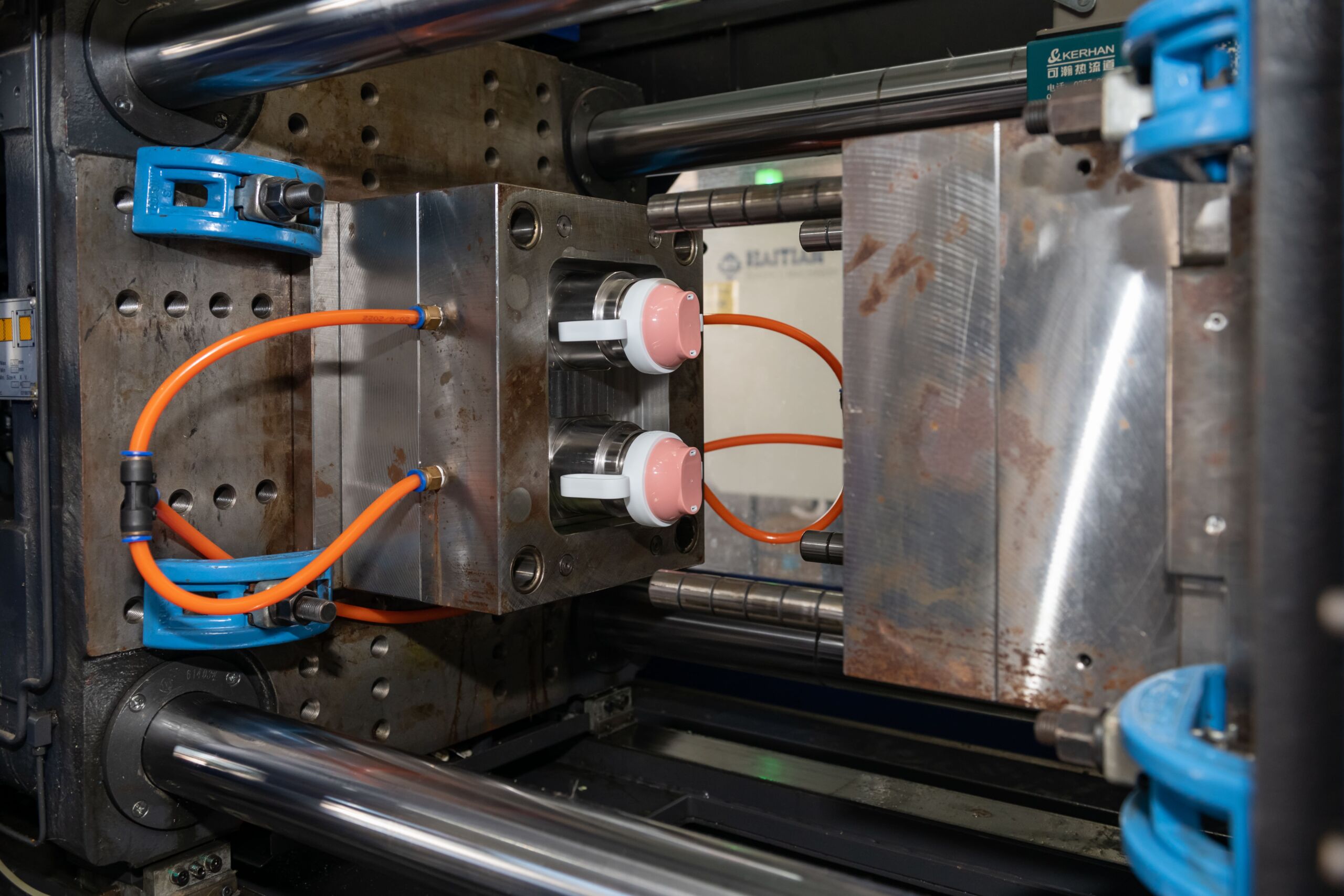

Plastic molding techniques encompass a variety of methods used to shape plastic materials into desired forms. Injection molding stands out as one of the most widely used techniques. This process involves injecting molten plastic into a mold cavity, which cools and solidifies into the desired shape. While injection molding offers high production rates and intricate designs, its environmental impact warrants scrutiny.

2. Assessing the Injection Molding Process

The injection molding process consumes significant energy and resources. From melting the plastic pellets to cooling and ejecting the final product, each step demands energy inputs, contributing to carbon emissions. Moreover, the reliance on petroleum-based plastics exacerbates environmental concerns, including resource depletion and pollution.

3. Sustainable Solutions in Polymer Molding Methods

To mitigate the environmental impact of plastic injection molding, industry players are increasingly adopting sustainable practices. This includes exploring biodegradable and recyclable plastics as alternatives to conventional materials. Additionally, optimizing manufacturing processes for energy efficiency and waste reduction is paramount. By embracing eco-friendly polymer molding methods, manufacturers can minimize their carbon footprint and contribute to a greener future.

4. Advancements in Mold Design for Plastics

Efficient mold design plays a crucial role in enhancing the sustainability of plastic injection molding. Manufacturers can reduce cycle times and energy consumption by optimizing mold geometry and incorporating innovative features such as cooling channels. Furthermore, utilizing durable materials for molds ensures longevity and minimizes waste generation, aligning with sustainable principles.

Read More – How Kasem Delivers Consistent Excellence in Mold Making

5. Embracing Precision Injection Molding for Sustainability

Precision injection molding enables the production of intricate and dimensionally accurate components with minimal material waste. Manufacturers can achieve higher quality outputs by precisely controlling variables such as temperature, pressure, and injection speed while minimizing resource consumption. This precision enhances product performance and reduces environmental impact through efficient use of materials.

6. Towards a Greener Future: Sustainable Plastic Injection Molding Practices

As demand for plastic injection molding services continues to rise, the industry must prioritize sustainability. Custom plastic molding companies increasingly invest in renewable energy sources, such as solar and wind power, to power their operations. Additionally, implementing closed-loop recycling systems enables the reuse of plastic waste generated during manufacturing processes, closing the loop on resource utilization.

In conclusion, while plastic injection molding offers unparalleled efficiency and versatility in manufacturing, its environmental impact cannot be ignored. The industry can mitigate its ecological footprint by embracing sustainable practices, such as utilizing eco-friendly materials, optimizing processes, and investing in renewable energy. As consumers and businesses prioritize environmental stewardship, adopting sustainable plastic injection molding techniques becomes a responsibility and an opportunity for innovation and progress.

At Kasem International, we recognize the importance of environmental sustainability in manufacturing. Through our commitment to eco-friendly practices and continuous improvement, we strive to minimize our environmental impact while delivering high-quality plastic injection molding services. Join us in our journey towards a greener future.

For more information on our sustainable manufacturing practices, visit our website at kasem-international.com.

February 12, 2024

February 12, 2024